Confectionery

AFC is a major supplier of chocolate wrapping and heat-seal foil to the Confectionery industry

AFC has received recognition as supplier of the year at Tiger Brands and Fair Cape Dairies.

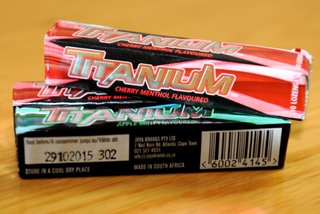

UNLAMINATED ALUFOIL, ONE SIDE VARNISHED AND/OR PRINTED, THE OTHER HEATSEAL COATED

ALUFOIL, PAPER AND WAX COMBINATIONS

UNLAMINATED ALUFOIL, ONE SIDE VARNISHED AND / OR PRINTED